Mild Dispersing温和分散的原理

Mild Dispersing

Our Original “Mild Dispersing” Technology

That Suppresses Damage to Particles

轻微的分散

我们独创的“温和分散”技术

这抑制了对粒子的损害

To grind and/or disperse particles down to nano size, suppressing damage to particles is a crucial factor.

Mild dispersing, our original technology, enables dispersion while maintaining the size, shape, crystal structure, and surface conditions of primary particles, as well as preventing re-agglomeration by minimizing the impact on particles and surface activation.

要将颗粒研磨和/或分散到纳米尺寸,抑制对颗粒的破坏是一个关键因素。

温和分散是我们独创的技术,在分散的同时保持原始颗粒的大小、形状、晶体结构和表面条件,并通过最大限度地减少对颗粒和表面活化的影响来防止再团聚。

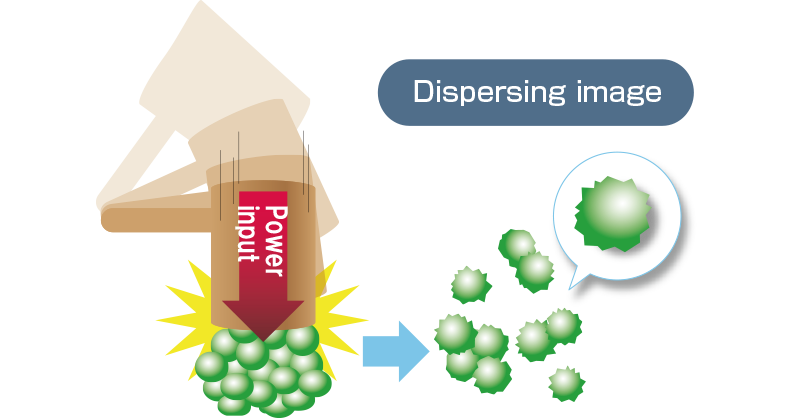

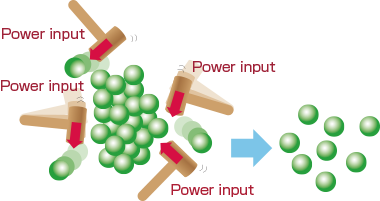

After Conventional Dispersing

Due to excessive dispersing, particles are susceptible to damage, resulting in re-agglomeration.

Particle properties are also susceptible to damage.

常规分散后

由于过度分散,颗粒容易受到破坏,导致再团聚。

粒子的特性也容易受到破坏。

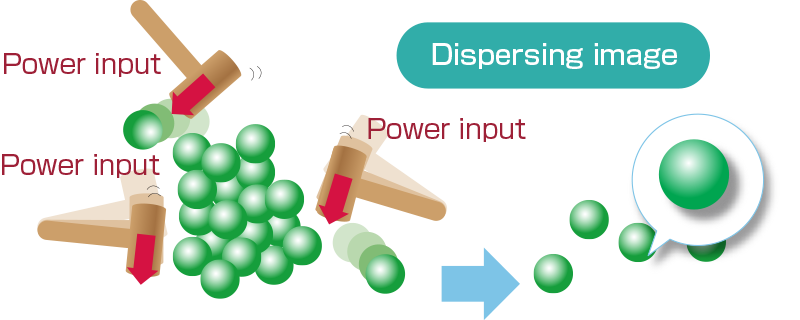

Mild Dispersing

Mild dispersing enables production of high quality and high-precision fine particles without excessive dispersing and damage.

轻微的分散

温和的分散使生产高质量和高精度的细颗粒,而不会过度分散和损坏。

Advantages of Mild Dispersing

Maintained particle properties

No re-agglomeration

Reduce additives amount

温和分散的优点

保持粒子特性

没有再聚集

减少添加剂用量

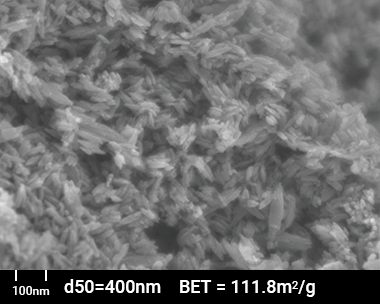

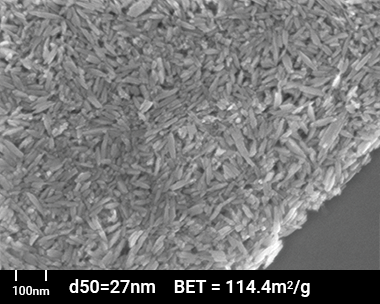

Example of Mild Dispersing

Mild dispersing : Dispersing while maintaining the needle-like shape.

温和分散的例子

温和分散:分散时保持针状。

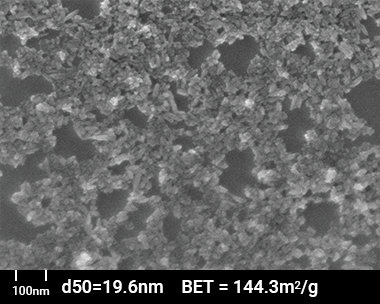

Case Example of TiO2

案例示例:二氧化钛

Raw material原材料

After conventional dispersing常规分散后

After mild dispersing温和分散后

Ideal Beads’ Movement

”Spiral Laminar Flow“

理想珠子运动

“螺旋层流”

Dispersing image分散图片

Bead movement珠子运动

Bead movement inside he grinding chamber

珠子在磨腔内运动

MAX NANO GETTER

Features of the MAX NANO GETTER HFM

The special agitator and rectification member form a spiral laminar flow, resulting in no dead space or congested points inside the grinding chamber. With this feature, beads are uniformly distributed, applying proper energy to particles and enabling effective dispersion.

Moreover, the MAX NANO GETTER HFM is a bead mill structured with a stirrer mechanism that facilitates self-dispersion by causing shear force and friction between particles in the slurry flow.

MAX NANO GETTER HFM特点

特殊的搅拌器和精馏部件形成螺旋层流,导致磨腔内无死区或堵塞点。有了这个特性,珠子均匀分布,给粒子施加适当的能量,使有效的分散。

此外,MAX NANO GETTER HFM是一种带有搅拌机构的磨头机,通过在浆体流动中产生剪切力和颗粒之间的摩擦来促进自分散。

Points to Consider When Operating Conventional

Bead Mills While Suppressing Damage

常规操作时需要考虑的问题

压制伤害的同时珠磨

1. Stable use of microbeads

In general, beads with a diameter of 0.03 mm to 2.0 mm are used in bead mills. However, when employing the mild dispersing of nano particles, use minute beads with tens to one hundred micrometers.

By using minute beads, more beads can be present per unit volume, increasing the probability of contact between particles and beads.

In addition, as the mass per bead falls, particles can be dispersed without damage.

1. 稳定使用微珠

一般来说,珠磨机使用的珠粒直径为0.03毫米至2.0毫米。然而,当使用纳米颗粒的温和分散时,使用几十到100微米的微小珠子。

通过使用微珠,每单位体积可以存在更多的微珠,增加颗粒和微珠之间接触的可能性。

此外,随着每颗珠子的质量下降,颗粒可以分散而不受损害。

2. Reduction of the bead filling ratio

In combination with the use of minute beads, reduce the amount of beads to fill relative to the grinding chamber volume. However, while damage to particles can be suppressed by reducing the bead filling ratio, this may affect grinding efficiency.

2. 降低珠子填充率

结合使用微珠,减少微珠的填充量相对于研磨室的体积。然而,虽然可以通过降低磨粒填充率来抑制颗粒的破坏,但这可能会影响研磨效率。

3. Reduction of the agitator's circumferential speed

Reduce the circumferential speed of the agitator. However, while damage to particles can be suppressed by reducing the circumferential speed, this may require longer grinding time.

3. 降低搅拌器的转向速度

降低搅拌器的转向速度。然而,虽然可以通过降低转向速度来抑制对颗粒的破坏,但这可能需要更长的研磨时间。

As described above, damage to particles can be reduced by operating machines under conditions 1 to 3. However, the use of minute beads may affect operability, and the reduction of the agitator’s circumferential speed and bead filling ratio may decrease efficiency.

To solve these issues, the NANO GETTER series has been developed and it enables “ideal mild dispersing.”

如上所述,在条件1到3下操作机器可以减少对颗粒的损害。然而,微珠的使用可能会影响操作,并且搅拌器圆周速度和微珠填充比的降低可能会降低效率。

为了解决这些问题,NANO GETTER系列已经开发出来,它可以实现“理想的温和分散”。