珠磨技术的原理

What Is a Bead Mill?

Bead Mills That Offer Nanotechnology

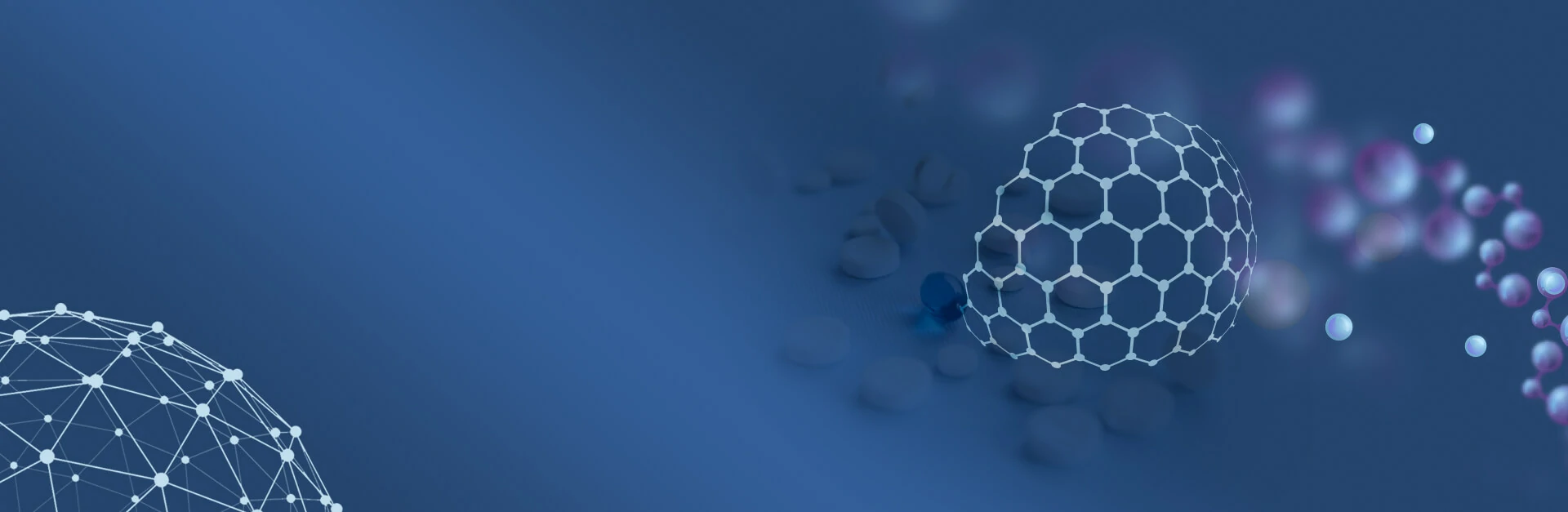

Bead mills are grinding and dispersing machines designed to grind and/or disperse particles down to the micro and nano scales. Beads (grinding media) inside the grinding chamber are agitated by rotating the shaft and the particles are ground and/or dispersed by the collision and shear force of the beads. The outlet of the grinding chamber has a filtering structure to separate beads from particles, retaining beads inside the chamber and enabling continuous production of fine particles.

什么是珠磨机?

提供纳米技术的珠磨

珠磨机是一种研磨和分散机器,用于研磨和/或分散颗粒到微纳米级。磨腔内的磨珠(研磨介质)通过轴的转动而被搅动,颗粒通过磨珠的碰撞和剪切力被磨碎和/或分散。研磨室出口具有过滤结构,将珠粒分离,将珠粒保留在研磨室内,实现细粒的连续生产。

Principles of Bead Mill Technology

珠磨技术原理

Dry Bead Mills

Dry bead mills employ a system to produce fine particles in air or inert gas atmosphere. With beads of relatively large diameter inside, large and coarse particles can be ground easily.

There are two types of dry bead mill operations: continuous or batch operations. Our dry bead mills adopt continuous (pass) operation capable of mass-producing fine particles.

干法珠磨机

干法珠磨机采用一种系统在空气或惰性气体气氛中生产细颗粒。内部有较大直径的珠子,可以很容易地研磨大而粗的颗粒。

有两种类型的干粒磨操作:连续或间歇操作。我们的干法珠磨机采用连续(通道)操作,可批量生产细粒。

Pass operation单程操作

Wet Bead Mills

Wet bead mills employ a system to produce fine particles in liquid. As the minute beads inside are agitated at high speed, the machines are capable of producing particles down to the nano size.

There are three types of wet bead mill operations: circulation, pass, and batch operations. We applies operation types according to the purpose of the products.

湿法珠磨机

湿法珠磨机采用一种系统在液体中产生细颗粒。由于内部的微珠高速搅拌,机器能够生产出小到纳米大小的颗粒。

有三种类型的湿法珠磨操作:循环,单程和批量操作。我们根据产品的用途,采用不同的操作方式。

Re-Circulation System循环系统

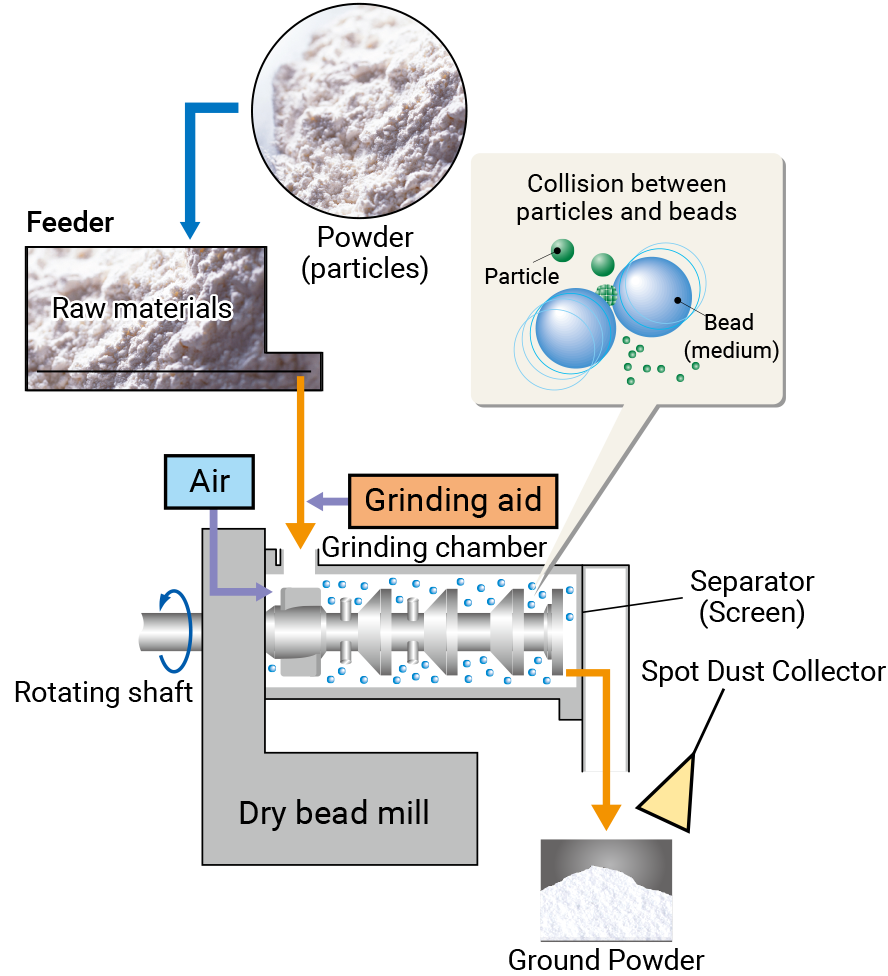

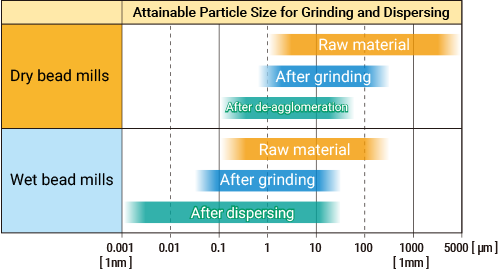

Comparison Between Dry and Wet Bead Mills

Dry processing is optimal for micro-size particles and wet processing is suitable for nano-size particles.

As beads with a relatively large diameter are employed in dry bead mills, large and coarse particles can be readily ground by vigorous agitation. As wet bead mills employ minute beads, finer particles can be produced with strong shear and friction force caused by agitating beads at high speed.

干湿法珠磨机的比较

干法处理微细颗粒为最佳,湿法处理纳米颗粒为最佳。

由于在干磨机中使用直径较大的珠粒,大而粗的颗粒可以通过剧烈的搅拌很容易地磨碎。由于湿式珠磨机采用的是微小的珠粒,因此可以利用高速搅拌珠粒所产生的强大剪切力和摩擦力来生产更细的颗粒。

Beads Used使用的珠子

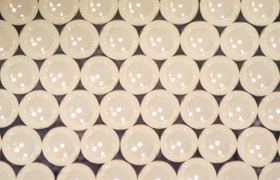

Beads (grinding media)

e.g. Photo of zirconia beads in 0.3 mm diameter

Size : 0.03 to 2 mm diameter

Material : Ceramic, glass, steel

珠(研磨介质)

例如:直径0.3 mm的氧化锆珠的照片

尺寸:0.03至2毫米直径

材质:陶瓷、玻璃、钢

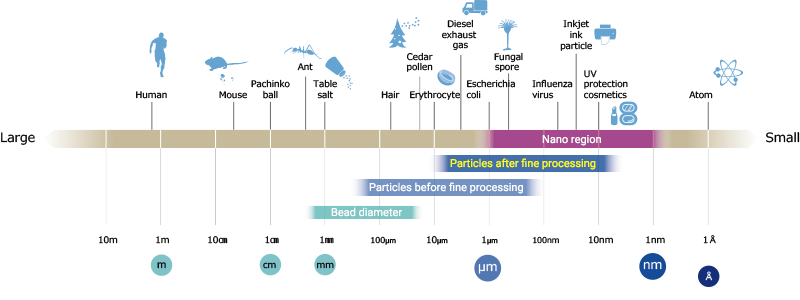

Comparison List of Object Sizes对象大小比较列表

1 nm (nanometer) = one thousandth of a micrometer = one billionth of a meter

1纳米=千分之一微米=十亿分之一米