NANO GETTER纳米颗粒分散机

Dispersing Machine for Mass-Producing Nano Particles

用于大规模生产纳米颗粒的分散机

MAX NANO GETTER

Mild Dispersing That Suppresses Damage to Particles

The MAX NANO GETTER is a bead mill for dispersing and mass-producing nano particles. This machine has performance equivalent to the existing NANO GETTER. With bead mills incorporating mixer and stirrer structures, it has been easy to scale up to increased volumes, enabling large-scale production of nano particles (around hundreds of kilograms per hour at maximum “the industry’s largest scale”). The MAX NANO GETTER can be used for various types of raw materials as the movement of beads can be easily controlled depending on the material type and change in viscosity.

温和分散,抑制对颗粒的损害

MAX NANO GETTER是用于分散和批量生产纳米颗粒的珠磨机。本机的性能与现有的NANO GETTER相当。由于珠磨机结合了混合器和搅拌器结构,很容易扩大规模,增加了产量,从而实现了纳米颗粒的大规模生产(最高每小时约数百公斤,是“行业最大规模”)。MAX NANO GETTER可用于各种类型的原材料,因为根据材料类型和粘度的变化可以轻松控制珠子的运动。

Features

Capable of mass-producing high-quality, high-precision nano particles

Supporting wide applications by setting mild dispersing, grinding, and optimal processing conditions

Reliable bead separation and stable use of microbeads (due to its adoption of the independently driven centrifugal separator)

特性

能够批量生产高质量、高精度的纳米颗粒

通过设置温和的分散,研磨和最佳的加工条件,支持广泛的应用

珠粒分离可靠,微珠使用稳定(采用独立驱动离心分离机)

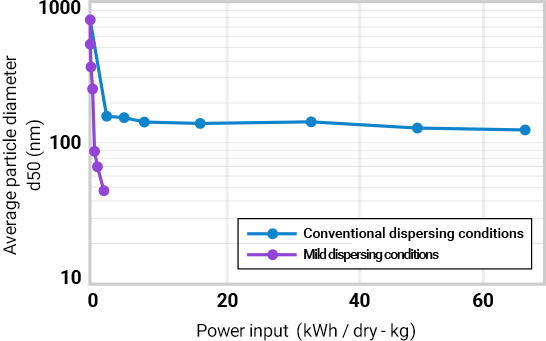

Example of Mild Dispersing

温和分散的例子

Cut down of Energy input

“Case Example of TiO2“

减少能量输入

“二氧化钛案例示例”

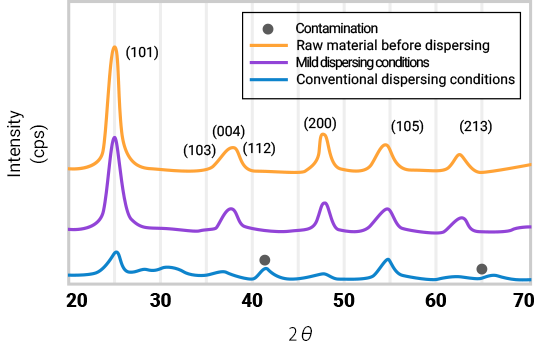

Keep particle properties

“Result of X‐ray diffraction”

保持粒子属性

“X射线衍射结果”

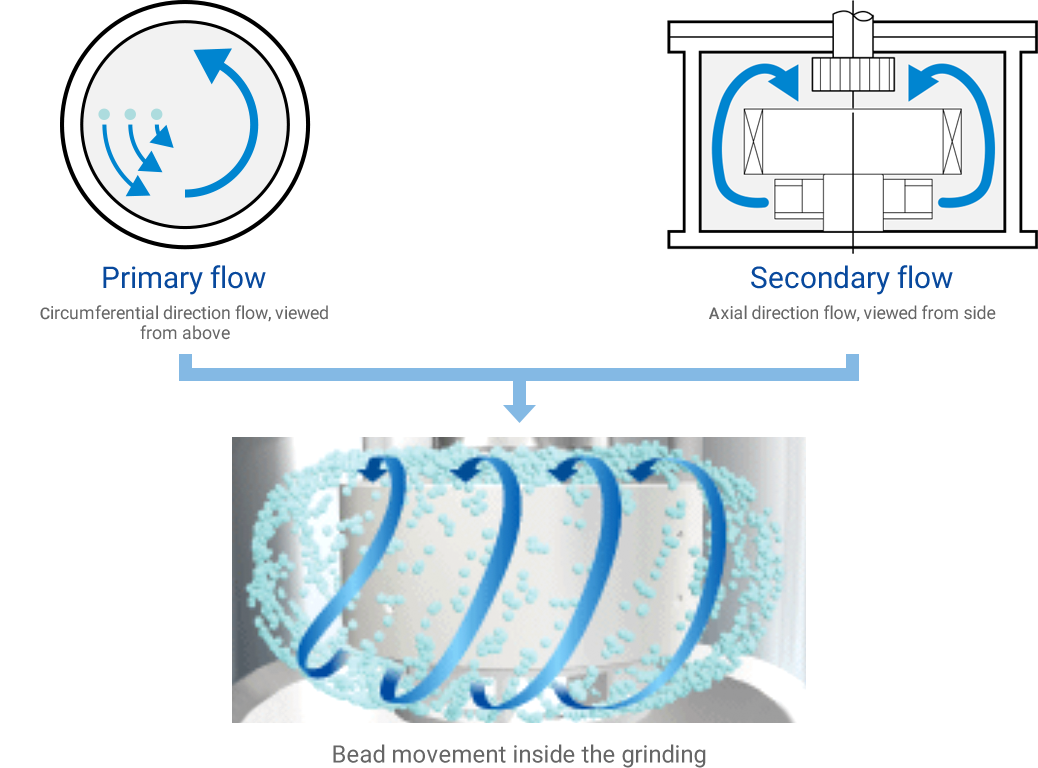

Ideal Beads’ Movement “Spiral Laminar Flow”

理想珠子的运动“螺旋层流”

Applications

Inkjet ink

Multi Layered Ceramic Capacitor

Photocatalysts

Automobile paint

Magnetic recording materials

Battery materials

Cosmetics

Pigments

Dyes

Semiconductor abrasive

Other applications of nano particles in general

应用

喷墨墨水

多层陶瓷电容器

光催化剂

汽车漆

磁性记录材料

电池材料

化妆品

颜料

染料

半导体磨料

纳米粒子的其他应用

Specifications规格

Model型号 | HFM02 – HFM125 |

Electric motor电机 | 2.2kW – 110kW |

Grinding chamber volume磨腔容积 | 0.2L – 125L |

Bead diameter珠子直径 | φ0.03mm – 0.5mm |